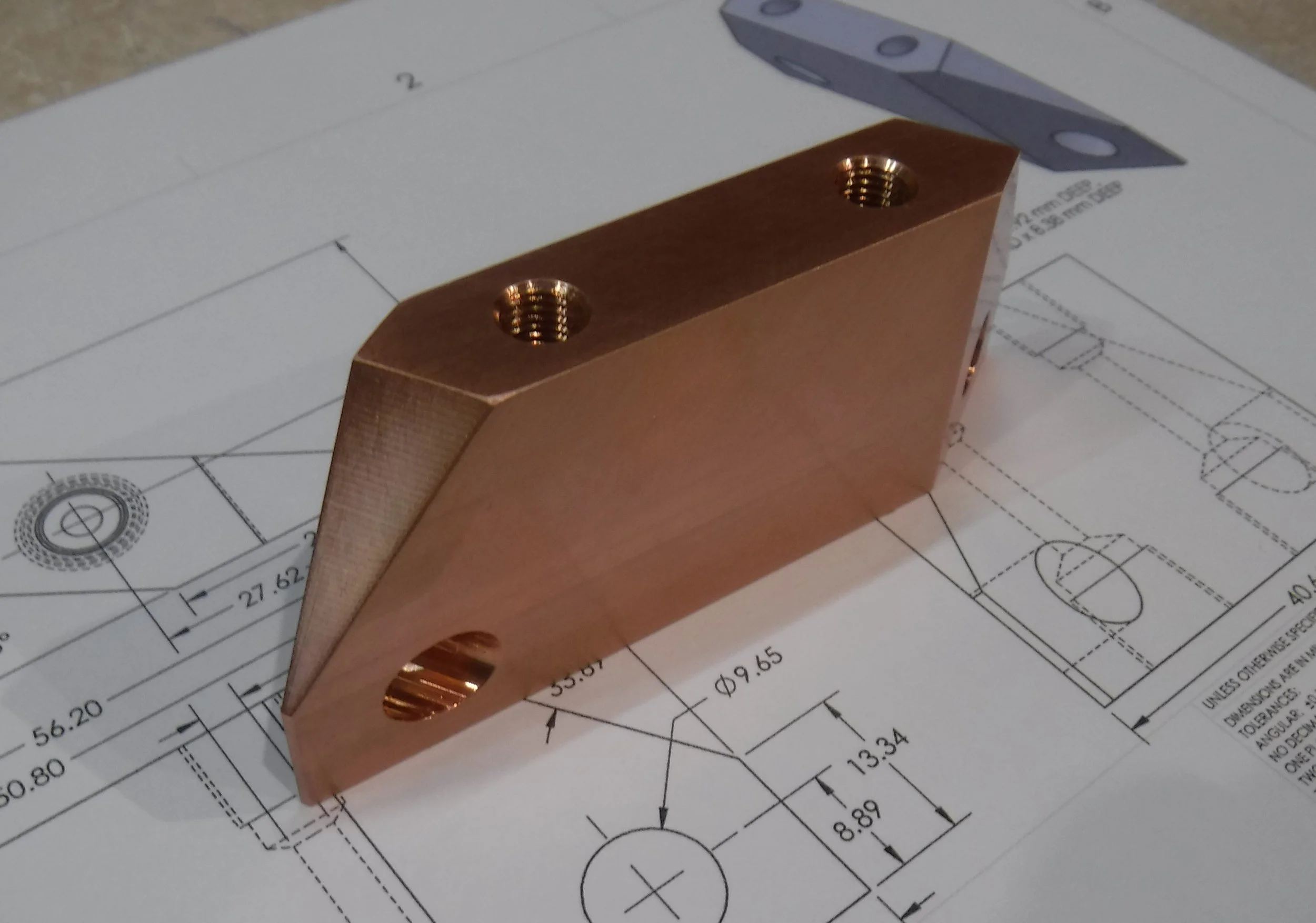

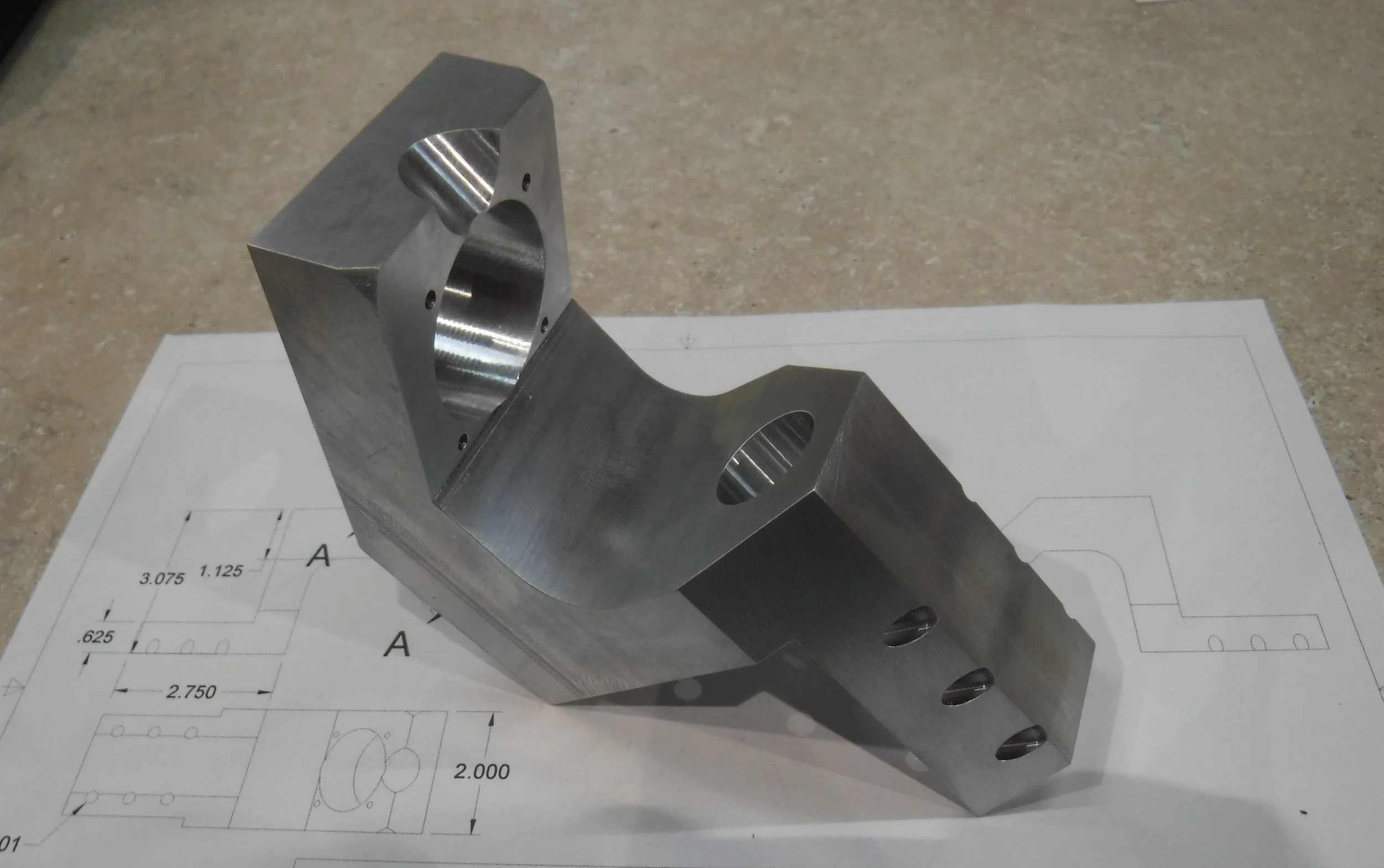

CNC Machining and CAM Programming Services

From prototype to full production, we provide economical high quality parts at Bray Precision. We also support other local machine shops through our CAM programming services and manufacturing process consultation.

3D Modeling, Fixture Design, DFM Analysis

If you need a replacement part that’s no longer supported, have an existing product that you want to optimize for manufacturing, or you just have an idea you want to make physical, we have the expertise to provide the solution.

Machining Services

-

We’ll cut most materials, but our preferred materials are:

Aluminum Alloys, Stainless Steels, Tool Steels, Plastics, Copper and Brass

We don’t cut composites such as Garolite (G10/FR4), or Graphite.

-

While we can mill many different size parts, see Work Envelopes below, the ideal parts for our machines and workflow are small enough to be loaded automatically via robot. Generally, smaller than a 4 inch (100mm) cube, with a weight under 6lbs (3kg). Automating part loading allows us to lower costs and improve quality, and as a result your parts will cost you less and be more consistent.

-

Similar to the Ideal Milling Parts, there is a turned part size which allows use to auto-feed material, and therefore offer a lowest cost to the customer. Generally, parts with a maximum outside diameter of 1 inch (25mm) are the ideal size for our workflow.

Machine Work Envelopes

Exceptions may be made depending on part geometry.

CNC Milling

Max part size is 20” x 16” x 12” (500mm x 400mm x 300mm).

CNC Turning

Max part size 6” diameter x 6” long (150mm diameter x 150mm long). Part quantities over 1000 parts must be <1” (25mm) Diameter in order to utilize automatic feeding.

Saw Cutting and Grinding

Sawing of material up to 14 inches (350mm) rectangular cross section, and up to 18 inches (450mm) in diameter.

Precision grinding offered as needed for small part runs.